What is Water Based PU?

Water-based leather is an environmentally friendly leather material made using a water-based coating process. It uses water as a solvent instead of traditional chemical solvents, significantly reducing volatile organic compound (VOC) emissions during production, making it more environmentally friendly and human-friendly.It can be used for surface treatment of genuine leather and can also be used to make synthetic leather (such as water-based PU leather), balancing environmental friendliness and practicality.

What is Recycled PU?

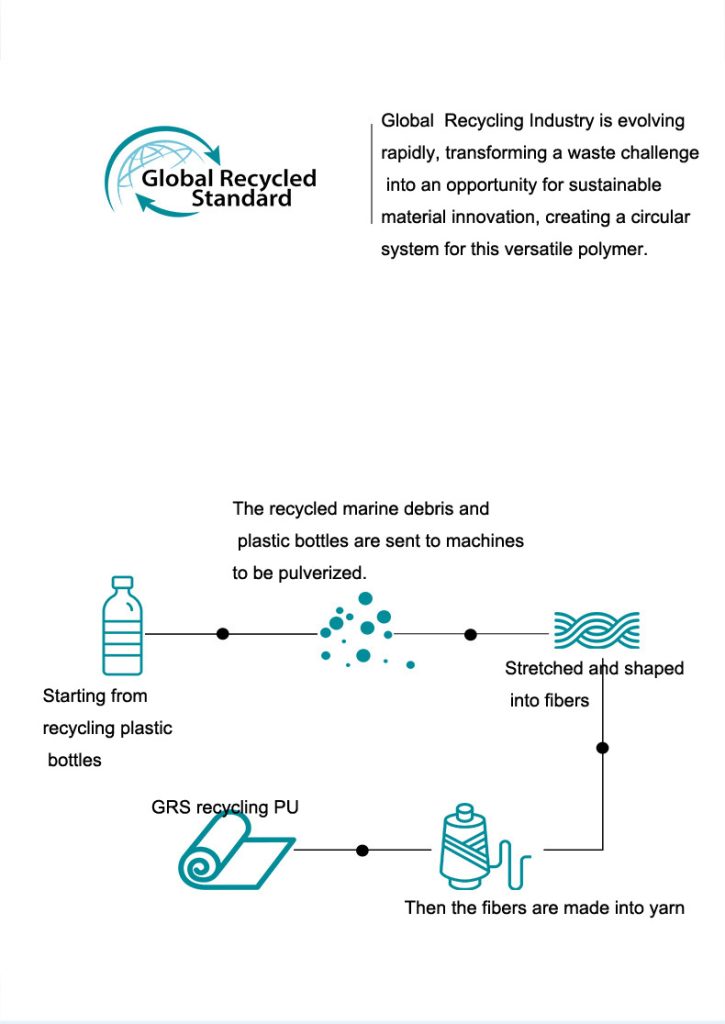

Recycled PU refers to materials made by recycling polyurethane (PU) waste or waste products and reprocessing them through physical or chemical treatment. It is mainly used in the manufacture of products such as foam plastics and artificial leather.

What are the differences between Water Based PU and recycled PU?

Waterbased PU and recycled PU are classifications of polyurethane materials from different perspectives. The former emphasizes environmentally friendly processes (using water as the dispersion medium), while the latter emphasizes the source of raw materials (including recycled resources). They differ significantly in production processes, environmental performance, physical properties, and application scenarios.

Production Process and Raw Material Source: Waterborne PU uses water as the dispersion medium and is made from waterborne polyurethane resin. The production process releases almost no volatile organic compounds (VOCs), avoiding the pollution of harmful substances such as formaldehyde found in traditional solvent-based leather. Recycled PU (often referring to recycled leather) is made by laminating PU material onto a base fabric (such as woven or non-woven fabric). The raw materials include leather waste or recycled fibers, and the process involves embossing, printing, and other techniques, with a greater emphasis on resource recycling.

Environmental Performance: Water-based PU has significant advantages in environmental protection. Because it uses water instead of toxic solvents, the production process is non-toxic and non-flammable, significantly reducing VOC emissions (by more than 70%), and leaving no harmful residues. While recycled PU indirectly reduces resource consumption by using recycled materials, its environmental performance depends on the specific process. Traditional PU lamination may still involve solvent use; however, some companies have developed biodegradable water-based environmentally friendly leather to improve sustainability.

Physical Properties and Performance: Water-based PU has good film-forming properties, with better moisture permeability and breathability than traditional solvent-based PU, and the film’s hardness can be adjusted (from soft to hard). However, its durability may be slightly inferior to solvent-based PU. Recycled PU combines the moisture absorption, breathability, and softness of genuine leather, and has good abrasion resistance, but its tensile strength is usually lower than that of genuine leather or PU leather of the same thickness, making it unsuitable for high-stress applications (such as shoe uppers). =

Application Scenarios:

Water-based PU is Widely used in furniture (such as sofas and mattresses), Handbags Factory, and automotive interiors, especially suitable for products for mothers and infants or people with sensitive skin

Recycled PU leather often uses microfiber or flocked fabric as the base material, and is made by electrostatic flocking and other processes using recycled PU resin. It is a type of recycled leather.